Incandescent lamps have had a near-monopoly on illumination for a century so it’s not surprising that lighting control equipment has closely tracked the needs of hot tungsten over the same period. However LEDs have different requirements.

Dimming incandescent lamps is simply a matter of selecting the desired intensity level. The lamp will automatically warm up or cool down with a pleasant lag, after which the new level is maintained. With LEDs we must carefully manage the transition between levels. Here’s why.

PWM Modulation

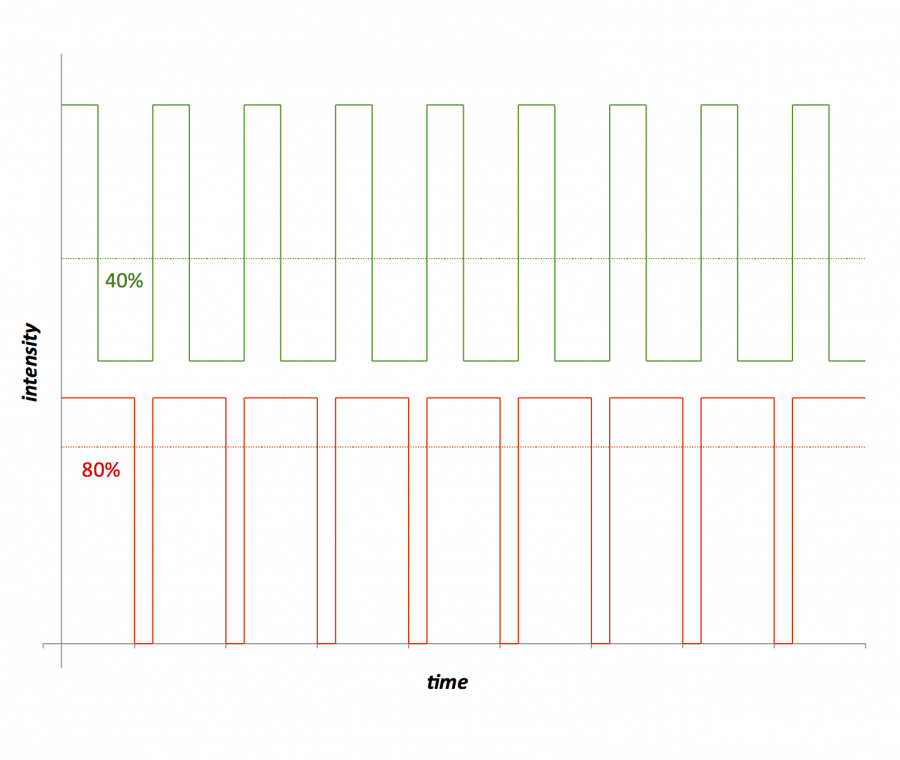

PWM (pulse-width modulation) has become almost ubiquitous for LED dimming. PWM turns the LEDs on and off in a cycle that repeats so quickly the eye fuses the transitions into an average brightness. The on‑period, or pulse width, determines the intensity percentage. So for example, if the LED is on for 40% of each cycle the intensity level is 40% as shown below.

With PWM the intensity level is changed simply by adjusting the pulse width, or on-period, while maintaining a constant cycle frequency. Note that there is a delay of up to one cycle before the change first appears. And it’s impossible for the intensity to change more than once per cycle. These will be important later.

Human Perception and Flicker

If the PWM cycle frequency is insufficient then the eye perceives flicker even without dimming. This point, known as the CFF (critical flicker frequency) in physiology, depends on many factors including the brightness of the stimulus, the light level of the viewing environment, the coverage of the visual field, relative eye and light source movement, and even the fatigue level of the observer. For example an LED with a low PWM frequency may create no visible flicker as a small pool of light, but can be very irritating if spread across an entire room—especially as the sole source of illumination.

Engineers usually choose a PWM frequency for LED lighting in the range of 80 to 1200 Hz (Hertz, or cycles per second.) The lower frequencies tend to generate visible flicker, while the higher frequencies require more sophisticated drive electronics and may emit audible noise.

High frequencies are not a panacea for visual artifacts. LED dimming using PWM has the inherent issue that the emitted light is actually a series of flashes that only simulates a lower average brightness. Any change in this series creates a transient response in the human visual system that may take many cycles to return to equilibrium. Even with a cycle time above the CFF threshold, transitions can still be visible—and still irritating.

This is not usually a problem for incandescent lamps since their lag tends to integrate pulses into a true constant light level, though the short lag of small filament lamps can cause flicker.

A Diversity of Dimming Controls

There are a tremendous variety of dimming controls from wall dimmers to theatrical lighting consoles. At the heart of all of them is one or more target intensity levels, whether entered by a person using a dial or lever, determined by sensors or timers, or computed according to a program. Many dimming controls also generate intensity ramps at various rates. These fade-up and fade-down periods can extend the life of incandescent lamps but also provide a more gracious aesthetic experience.

Intensity levels and transition ramps are the basic elements of lighting control, but attempts to apply these to LEDs using existing techniques has led to ugly results. This is because existing controls assume the natural smoothing of incandescent lamps where transient dips and spikes are ignored, jitter in the desired level is imperceptible, communication delays don’t matter, and ramping between levels can get by with a crude approximation of the actual visual effect desired. Unfortunately this kind of roughness is very visible with LEDs.