A dimming curve provides a static mapping between an input control level and an output drive power for a light source. Having been around for a century or so, their original purpose was to compensate for (or introduce) non-linearity. This is because:

- Analog dimmers did not necessarily have a linear output with respect to the control position,

- Tungsten lamps definitely do not have a linear light output versus the applied power,

- Different light sources output different intensities for the same applied power, and

- Various lighting applications need finer control at higher or lower light levels.

For example, tungsten lamps are black body radiators so most of their energy at low power levels is in the infrared end of the spectrum. The applied power has to be fairly high before any visible light is emitted. A compensating dimming curve is steeper at low intensities and flatter at high intensity levels.

Sometimes Size Matters

Another lighting issue that’s been around “forever” is the dimming of small-filament lamps. Typical tungsten filaments take considerable time to heat up and cool down, making for smooth operation. This effectively filters out any small transients in the applied power. However small-filament lamps are very quick to respond. This is useful for some applications, like chase lights or animated signs, but it can be a challenge when adjusting light levels in a ballroom lit with hundreds of small lamps. Unless the applied power changes very smoothly the result is an irritating steppy flicker, especially at low lighting levels.

Most lighting designers have attempted to address the small-filament lamp problem with dimming curves at some point during their career. But one finds out fairly quickly that making the bottom of the curve smooth tends to make the rest of the curve rough. Sometimes one can find a happy medium, but perfection is elusive. I first saw LED-based luminaires for stage lighting in 2006, and they were rife with the small-filament problem–or its LED equivalent. Since LEDs respond infinitely faster than filaments this should not have been a surprise. So perhaps it was natural to attempt to apply dimming curves in an attempt to smooth the dimming. However it doesn’t entirely work, as you’ll see.

Failing to Make the Curve

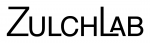

Dimming curves can improve linearity, synchronize light output of disparate fixtures, compensate for non-linear inputs, or concentrate precise control over a narrow range. What they cannot do is everything at once. Trying to solve every aspect of lighting control with a dimming curve is futile, and an abuse of the mechanism. Consider the following chart, showing various power law dimming curves:

The top curve, colored red, is an example of a compensating curve for a tungsten filament. Note it starts at about 6% intensity; this is a typical power level for a tungsten lamp to start producing light. (Theatrical dimmers usually apply some power at zero commanded intensity to “pre-heat” the filament for faster response.)

The next curve, colored orange with a 𝛾 of 2.0, represents the compensation necessary for the eye to see linear light output. Because the eye is more sensitive to lower light levels, this curve puts what appears to be half brightness in the middle of the control dial, assuming the light source has a linear output intensity for its control inputs. Video displays tend to use a gamma in the range of 1.8 to 2.2. The green curve (𝛾=3.0) shows an example of excessive compensation. Which brings us to…

Watch That Last Step

The last curve above illustrates is that prescribed by the DALI specification. It has a very large gamma, far in excessive of any compensation required for the human eye’s logarithmic response. When the input is 50%, the output is only 3%! DALI-compliant drivers and luminaires are designed to follow this curve, even if they utilize other compensation internally. I have been unable to find a reliable source of information on the reasoning behind the extreme gamma, but it appears to be an attempt to gain smoothness in the face of DALI’s 8-bit intensity resolution. Unfortunately this is really a terrible approach. Issues include:

- Poor correlation between control position and light output,

- Insufficient resolution at high brightness levels, and

- Still doesn’t solve the smoothness problem.

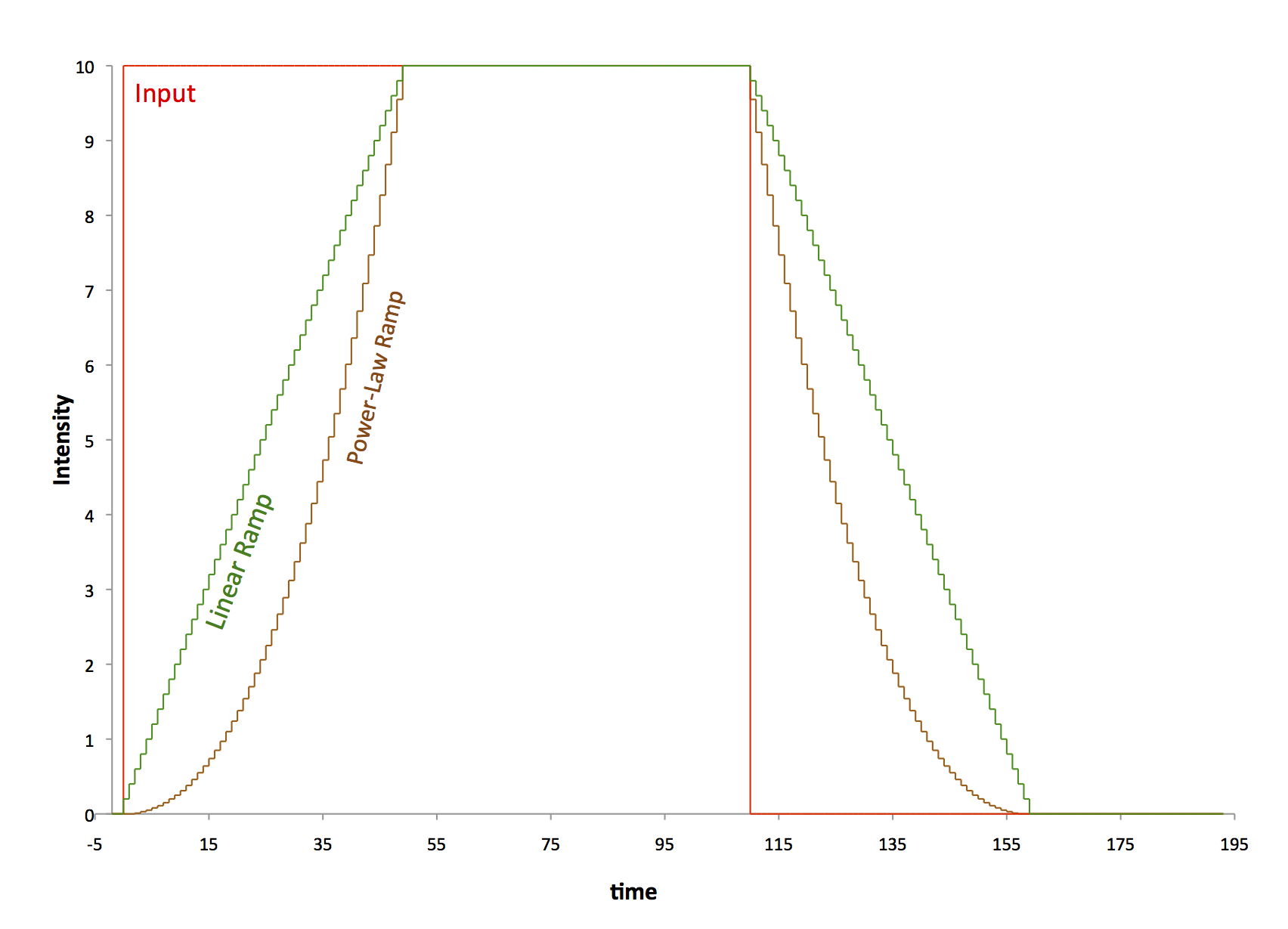

The following chart shows the discrete intensity steps for two methods of fading a light source on and off. While the power law dimming curve provides smooth fades down to black, the fades up to full have large steps which will be highly visible. With DALI the last step is 3% of full brightness!

Architectural fades tend to be fast-on, slow-off which may mitigate the rough fade-up issue in many cases. However in some situations–such as restoring illumination after using a projection screen–slow-on is highly desirable. This compromise is just so unnecessary. The root issue is that DALI is attempting to use a static dimming curve to achieve smoothness everywhere, which is impossible. For a better alternative, please see this post.